Anchor Bolt on:

[Wikipedia]

[Google]

[Amazon]

Anchor bolts are used to connect structural and non-structural elements to

Anchor bolts are used to connect structural and non-structural elements to

The simplest – and strongest – form of anchor bolt is cast-in-place, with its embedded end consisting of a standard hexagonal head bolt and washer, 90-bend, or some sort of forged or welded flange (see also

The simplest – and strongest – form of anchor bolt is cast-in-place, with its embedded end consisting of a standard hexagonal head bolt and washer, 90-bend, or some sort of forged or welded flange (see also

The force-transfer mechanism is based on

The force-transfer mechanism is based on

Bonded anchors are also referred as ''adhesive anchors'' or ''chemical anchors''. The anchoring material is an adhesive (also called ''mortar'') usually consisting of

Bonded anchors are also referred as ''adhesive anchors'' or ''chemical anchors''. The anchoring material is an adhesive (also called ''mortar'') usually consisting of

Their force-transfer mechanism is similar to mechanical expansion anchors. A torque moment is applied to a screw which is inserted in a plastic sleeve. As the torque is applied the plastic expands the sleeve against the sides of the hole acting as expansion force.

Their force-transfer mechanism is similar to mechanical expansion anchors. A torque moment is applied to a screw which is inserted in a plastic sleeve. As the torque is applied the plastic expands the sleeve against the sides of the hole acting as expansion force.

File:Steel Failure.png, Steel Failure

File:Concrete Cone Failure.png, Concrete Cone Failure

File:Pull-Out failure.png, Pull-Out Failure

File:Pull-Through failure.png, Pull-Through Failure

File:Blow Out Failure.png, Blow-Out Failure

File:Splitting Failure.png, Splitting Failure

File:Concrete Edge failure.png, Concrete Edge failure

File:Pry Out Failure.png, Pry-Out failure

In order to increase the load-carrying capacity anchors are assembled in group, moreover this allow also to arrange a bending moment resisting connection. For tension and shear load, the mechanical behavior is markedly influenced by (i) the spacing between the anchors and (ii) the possible difference in the applied forces.

In order to increase the load-carrying capacity anchors are assembled in group, moreover this allow also to arrange a bending moment resisting connection. For tension and shear load, the mechanical behavior is markedly influenced by (i) the spacing between the anchors and (ii) the possible difference in the applied forces.

File:Ancor bolt for concrete.JPG, Wedge type - 1

File:Betonanker.jpg, Expansion type

File:Fischer FH.jpg, Sleeve type

File:Metall-Fensterrahmendübel F10 M132 1756.JPG, Wedge type - 2

File:Bonded Anchor.png, Bonded Anchor

File:Concrete Screw.png, Concrete Screw

Anchor bolts are used to connect structural and non-structural elements to

Anchor bolts are used to connect structural and non-structural elements to concrete

Concrete is a composite material composed of fine and coarse aggregate bonded together with a fluid cement (cement paste) that hardens (cures) over time. Concrete is the second-most-used substance in the world after water, and is the most wi ...

.. The connection can be made by a variety of different components: anchor bolts (also named fasteners), steel plates, or stiffeners. Anchor bolts transfer different types of load: tension forces and shear force

In solid mechanics, shearing forces are unaligned forces acting on one part of a body in a specific direction, and another part of the body in the opposite direction. When the forces are collinear (aligned with each other), they are called t ...

s.

A connection between structural elements can be represented by steel columns attached to a reinforced concrete foundation. A common case of a non-structural element attached to a structural one is the connection between a facade system and a reinforced concrete wall.

Types

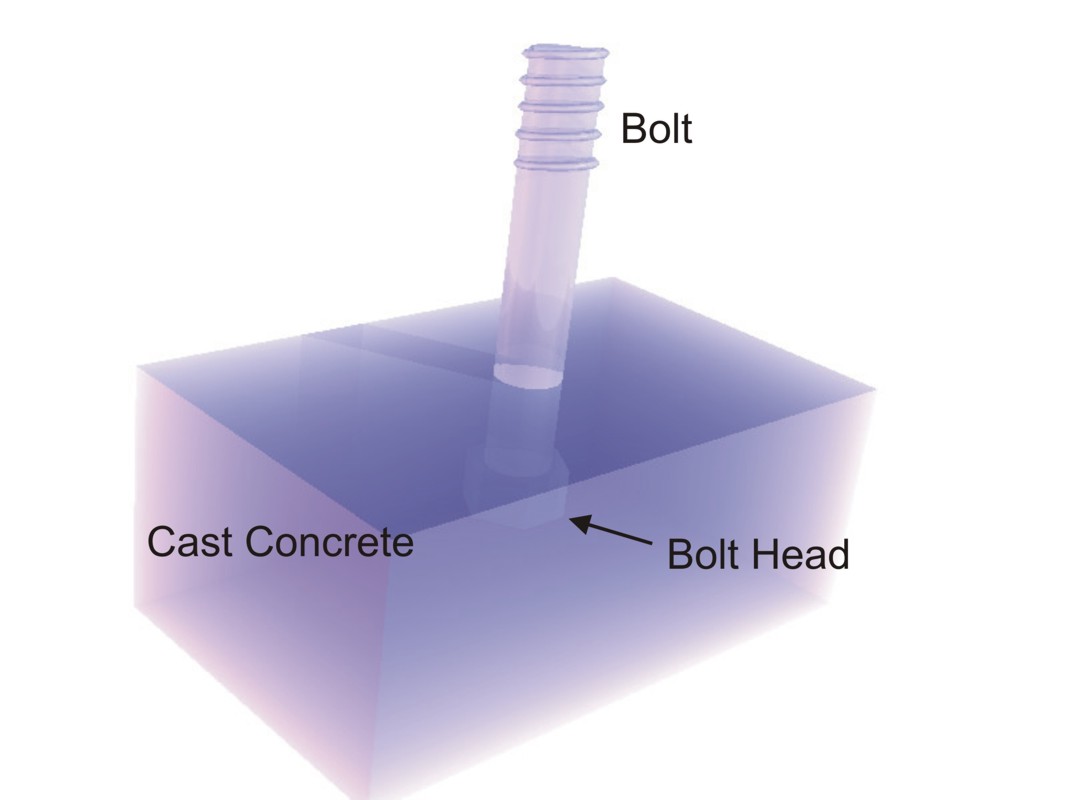

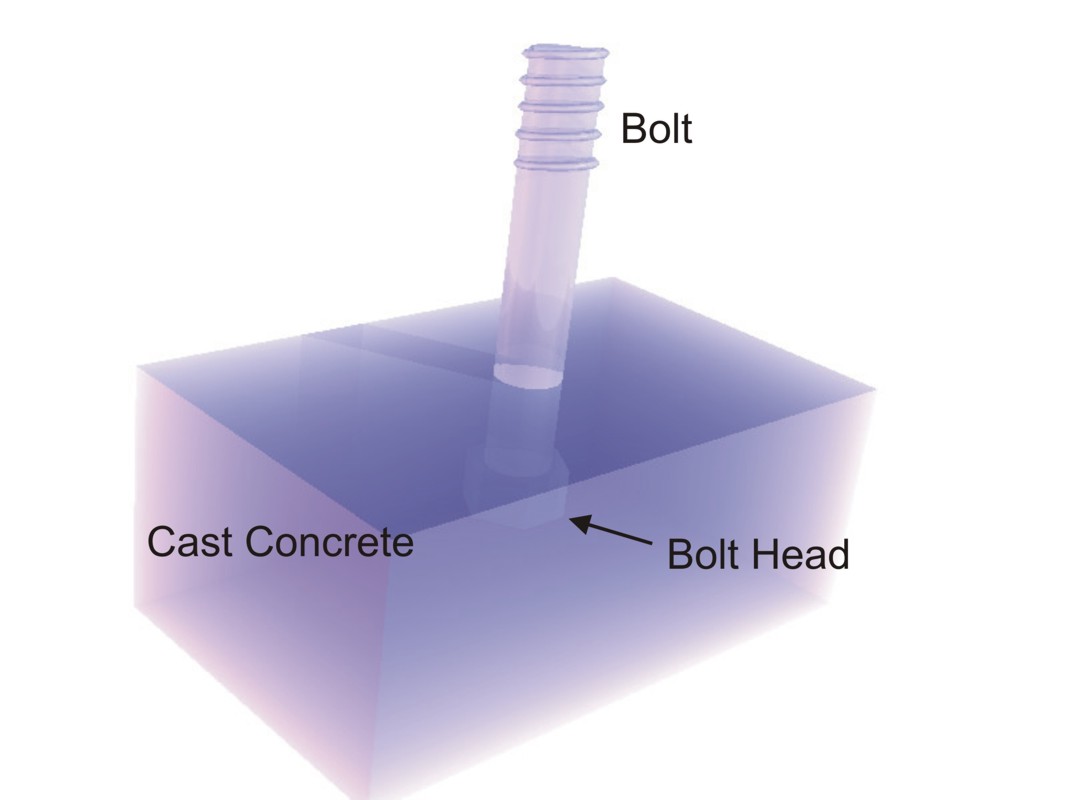

Cast-in-place

The simplest – and strongest – form of anchor bolt is cast-in-place, with its embedded end consisting of a standard hexagonal head bolt and washer, 90-bend, or some sort of forged or welded flange (see also

The simplest – and strongest – form of anchor bolt is cast-in-place, with its embedded end consisting of a standard hexagonal head bolt and washer, 90-bend, or some sort of forged or welded flange (see also stud welding

Stud welding is a technique similar to flash welding where a fastener or specially formed nut is welded onto another metal part, typically a base metal or substrate. The fastener can take different forms, but typically fall under threaded, unth ...

). The last are used in concrete-steel composite structures as shear connectors.

Other uses include anchoring machines to poured concrete floors and buildings to their concrete foundations.

Various typically disposable aids, mainly of plastic, are produced to secure and align cast-in-place anchors prior to concrete placement. Moreover, their position must also be coordinated with the reinforcement

In behavioral psychology, reinforcement is a consequence applied that will strengthen an organism's future behavior whenever that behavior is preceded by a specific antecedent stimulus. This strengthening effect may be measured as a higher freq ...

layout. Different types of cast-in-place anchors might be distinguished:

* Lifting inserts: used for lifting operations of plain or prestressed RC beams. The insert can be a threaded rod. See also bolt (climbing)

In rock climbing, a bolt is a permanent anchor fixed into a hole drilled in the rock as a form of protection. Most bolts are either self-anchoring expansion bolts or fixed in place with liquid resin.

Description

While bolts are commonplace in ...

.

* Anchor channels: used in precast concrete connections. The channel can be a hot-rolled or a cold-formed steel shape in which a T-shape screw is placed in order to transfer the load to the base material.

* Headed stud: consist of a steel plate with headed studs welded on (see also threaded rod

A threaded rod, also known as a stud, is a relatively long rod that is threaded on both ends; the thread may extend along the complete length of the rod. They are designed to be used in tension. Threaded rod in bar stock form is often called all ...

).

* Threaded sleeves: consist of a tube with an internal thread which is anchored back into the concrete.

For all the type of the cast-in-place anchors, the load-transfer mechanisms is the mechanical interlock, i.e. the embedded part of the anchors in concrete transfers and the applied load (axial or shear) via bearing pressure at the contact zone. At failure conditions, the level of bearing pressure can be higher than 10 times the concrete compressive strength, if a pure tension force is transferred.

Cast-in-place type anchors are also utilized in masonry applications, placed in wet mortar joints during the laying of brick and cast blocks ( CMUs).

Post-installed

Post-installed anchors can be installed in any position of hardened concrete after a drilling operation. A distinction is made according to their principle of operation.Mechanical expansion anchors

The force-transfer mechanism is based on

The force-transfer mechanism is based on friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. There are several types of friction:

*Dry friction is a force that opposes the relative lateral motion of t ...

mechanical interlock guaranteed by expansion forces. They can be furtherly divided into two categories:

* torque controlled: the anchor is inserted into the hole and secured by applying a specified torque to the bolt head or nut with a torque wrench

A torque wrench is a tool used to apply a specific torque to a fastener such as a nut, bolt, or lag screw. It is usually in the form of a socket wrench with an indicating scale, or an internal mechanism which will indicate (as by 'clicking', a ...

. A particular sub-category of this anchor is called ''wedge type''. As shown in the figure, tightening the bolt results in a wedge being driven up against a sleeve, which expands it and causes it to compress against the material it is being fastened to.

* displacement controlled: usually consist of an expansion sleeve and a conical expansion plug, whereby the sleeve is internally threaded to accept a threaded element.

Undercut anchors

The force-transfer mechanism is based on mechanical interlock. A special drilling operation allows to create a contact surface between the anchor head and the hole's wall where bearing stresses are exchanged.Bonded anchors

Bonded anchors are also referred as ''adhesive anchors'' or ''chemical anchors''. The anchoring material is an adhesive (also called ''mortar'') usually consisting of

Bonded anchors are also referred as ''adhesive anchors'' or ''chemical anchors''. The anchoring material is an adhesive (also called ''mortar'') usually consisting of epoxy

Epoxy is the family of basic components or cured end products of epoxy resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also coll ...

, polyester

Polyester is a category of polymers that contain the ester functional group in every repeat unit of their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include natural ...

, or vinylester Vinyl ester resin, or often just vinyl ester, is a resin produced by the esterification of an epoxy resin with acrylic or methacrylic acids. The "vinyl" groups refer to these ester substituents, which are prone to polymerize and thus an inhibitor is ...

resins.

In bonded anchors, the force-transfer mechanism is based on bond stresses provided by binding organic materials. Both ribbed bars and threaded rod

A threaded rod, also known as a stud, is a relatively long rod that is threaded on both ends; the thread may extend along the complete length of the rod. They are designed to be used in tension. Threaded rod in bar stock form is often called all ...

s can be used and a change of the local bond mechanism can be appreciated experimentally. In ribbed bars the resistance is prevalently due to shear behavior of concrete between the ribs whereas for threaded rods friction prevails (see also anchorage in reinforced concrete Reinforced concrete Cis concrete in which reinforcement bars (" rebars"), reinforcement grids, plates or fibers are embedded to create bond and thus to strengthen the concrete in tension. The composite material was invented by French gardener J ...

).

The performance of this anchor's types in terms of 'load-bearing capacity', especially under tension loads, is strictly related to the cleaning condition of the hole. Experimental results showed that the reduction of the capacity is up to 60%. The same applies also for moisture condition of concrete, for wet concrete the reduction is of 20% using polyester resin Polyester resins are synthetic resins formed by the reaction of dibasic organic acids and polyhydric alcohols. Maleic anhydride is a commonly used raw material with diacid functionality in unsaturated polyester resins. Unsaturated polyester res ...

. Other issues are represented by high temperature behavior and creep response..

Screw anchors

The force-transfer mechanism of the screw anchor is based on concentrated pressure exchange between the screw and concrete through the pitches.Plastic anchors

Their force-transfer mechanism is similar to mechanical expansion anchors. A torque moment is applied to a screw which is inserted in a plastic sleeve. As the torque is applied the plastic expands the sleeve against the sides of the hole acting as expansion force.

Their force-transfer mechanism is similar to mechanical expansion anchors. A torque moment is applied to a screw which is inserted in a plastic sleeve. As the torque is applied the plastic expands the sleeve against the sides of the hole acting as expansion force.

Tapcon screws

Tapcon screws are a popular anchor that stands for ''self tapping'' (self threading) concrete screw. Larger diameter screws are referred to as LDT's. This type of fastener requires a pre-drilled hole—using a Tapcon drillbit—and are then screwed into the hole using a standard hex or phillips bit. These screws are often blue, white, or stainless. They are also available in versions for marine or high stress applications.Powder-actuated anchors

They act transferring the forces via mechanical interlock. This fastening technology is used in steel-to-steel connection, for instance to connect cold-formed profiles. A screw is inserted into the base material via a gas actuated gas gun. The driving energy is usually provided by firing a combustible propellant in powder form. The fastener's insertion provokes the plastic deformation of the base material which accommodates the fastener's head where the force transfer takes place.Mechanical behavior

Modes of failure in tension

Anchors can fail in different way when loaded in tension: * Steel failure: the weak part of the connection is represented by the rod. The failure corresponds to the tensile break-out of steel as in case oftensile testing

Tensile testing, also known as tension testing, is a fundamental materials science and engineering test in which a sample is subjected to a controlled tension until failure. Properties that are directly measured via a tensile test are ultimate ...

. In this case, concrete base material might be undamaged.

* Pull-out: the anchor is pulled out from the drilled hole partially damaging the surrounding concrete. When the concrete is damaged the failure is also indicated as ''pull-through''.

* Concrete cone: after reaching the load-bearing capacity a cone shape is formed. The failure is governed by crack growth in concrete. This kind of failure is typical in pull-out test.

* Splitting failure: failure is characterized by a splitting crack which divides the base material into two parts. This kind of failure occurs when the dimensions of the concrete component are limited or the anchor is installed close to an edge.

* Blow-out failure: failure is characterized by the lateral spalling of concrete in the proximity of the anchor's head. This kind of failure occurs for anchors (prevalently cast-in-place) installed near the edge of the concrete element.

In design verification under ultimate limit state, codes prescribe to verify all the possible failure mechanisms.

Modes of failure in shear

Anchors can fail in different way when loaded in shear: * Steel failure: the rod reaches the yielding capacity then rupture occurs after development of large deformations. * Concrete edge: a semi-conical fracture surface develops originating from the point of bearing up to the free surface. This type of failure occurs, for an anchor in the proximity of the edge of the concrete member. * Pry-out: a semi-conical fracture surface develops characterize the failure. The pryout mechanism for cast-in anchors usually occurs with very short, stocky ''studs''. The studs are typically so short and stiff that under a direct shear load, they bend causing contemporarily crushing in front of the stud and a crater of concrete behind. In design verification under ultimate limit state, codes prescribe to verify all the possible failure mechanisms.Combined tension/shear

When contemporarily tension and shear load are applied to an anchor the failure occurs earlier (at a less load-bearing capacity) with respect the un-coupled case. In current design codes a linear interaction domain is assumed.Group of anchors

In order to increase the load-carrying capacity anchors are assembled in group, moreover this allow also to arrange a bending moment resisting connection. For tension and shear load, the mechanical behavior is markedly influenced by (i) the spacing between the anchors and (ii) the possible difference in the applied forces.

In order to increase the load-carrying capacity anchors are assembled in group, moreover this allow also to arrange a bending moment resisting connection. For tension and shear load, the mechanical behavior is markedly influenced by (i) the spacing between the anchors and (ii) the possible difference in the applied forces.

Service load behavior

Under service loads (tension and shear) anchor's displacement must be limited. The anchor performance (load-carrying capacity and characteristic displacements) under different loading condition is assessed experimentally, then an official document is produced by technical assessment body. In design phase, the displacement occurring under the characteristic actions should be not larger than the admissible displacement reported in the technical document.Seismic load behavior

Under seismic loads and there would be the possibility that an anchor is contemporarily (i) installed in a crack and (ii) subjected to inertia loads proportional both to the mass and the acceleration of the attached element (''secondary structure'') to the base material (''primary structure''). The load conditions in this case can be summarized as follow: * Pulsating Axial load: force aligned with the anchor's axis, positive in case of pullout condition and zero in case of pushing-in. * Reverse Shear load (also named “alternate shear”): force perpendicular to the anchor's axis, positive and negative depending on an arbitrary sign convention. * Cyclic Crack (also named “crack movement”): RC primary structure undergoes in severe damage condition (i.e. cracking) and the most un-favorable case for anchor performance is when the crack plane contains the anchor's axis and the anchor is loaded by a positive axial force (constant during crack cycles).Exceptional loads behavior

Exceptional loads differ from ordinary static loads for their rise time. High displacement rates are involved in impact loading. Regarding steel to concrete connections, some examples consist in collision of vehicle on barriers connected to concrete base and explosions. Apart from these extraordinary loads, structural connections are subjected to seismic actions, which rigorously have to be treated via dynamic approach. For instance, seismic pull-out action on anchor can have 0.03 seconds of rise time. On the contrary, in a quasi-static test, 100 second may be assumed as time interval to reach the peak load. Regarding the concrete base failure mode: Concrete cone failure loads increase with elevated loading rates with respect the static one.Designs

See also

*Well nut

A well nut is a blind rivet-like type of fastener used to blindly fasten a piece (much like a molly bolt) and to seal the bolt hole.

They are often referred to by the proprietary name Rawlnut or Rawl nut, the name by which they are known in the ...

References

{{Cite web , title=ETA seismic approval concrete screw , url=https://screwanchor.com.tw/eta-seismic-approval-sissy-stud , website=Joker Industrial Structural connectors Threaded fasteners Wall anchors